- Home

- Production Equipment

- Solid Material Preparation

- Solid Dosage Forms

- Liquid Dosage Forms

- Packing Machine

- About Us

- Service

- News

- Contact Us

Oral Liquid Bottle Integrated Production Line

The entire production line will be fully customized according to the product requirements, including bottle type, filling contents, filling volume, filling speed, etc.

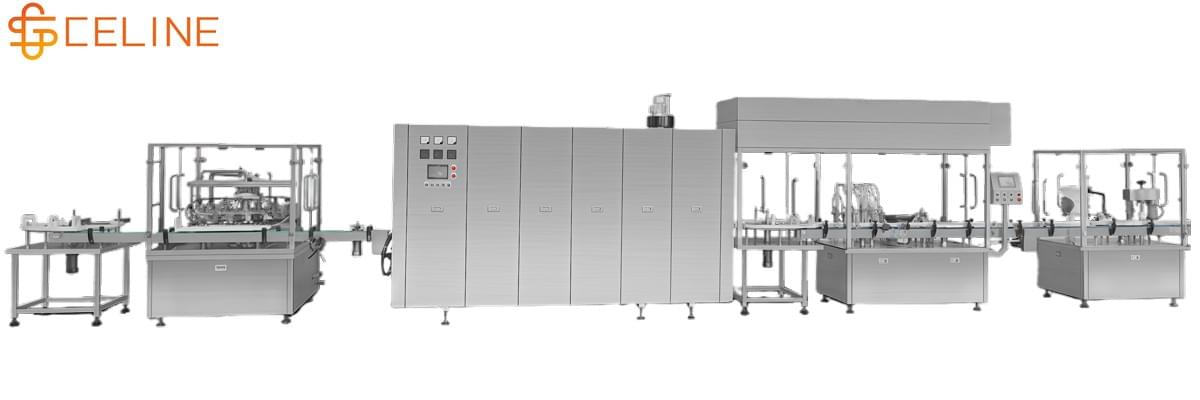

30-150ml High-speed Oral Liquid Filling Production Line

This production line consists of a bottle washing machine, a hot air circulating tunnel oven, a connecting conveyor belt, and a high-speed filling and capping machine, forming a coordinated production line. It is suitable for the production of round or irregularly shaped glass bottles.

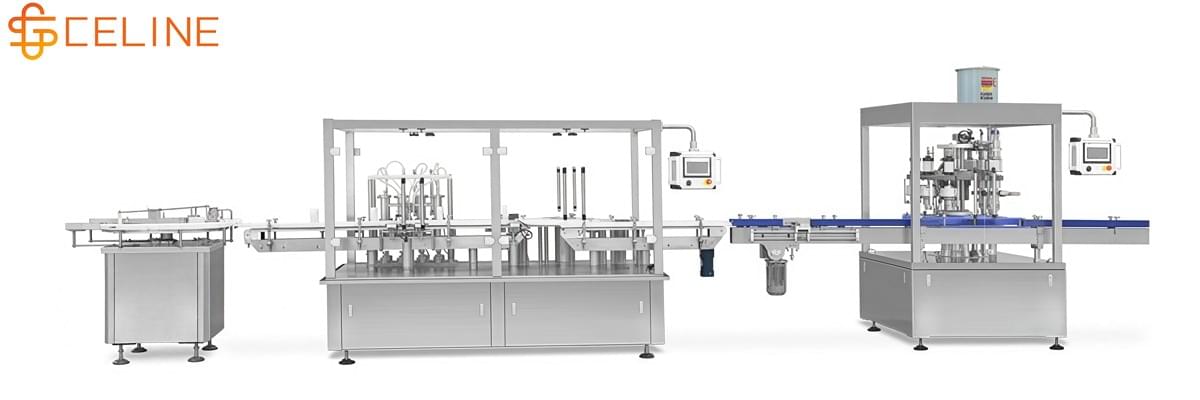

10-20ml Oral Liquid Bottle Filling Production Line

It is mainly used for cleaning, drying, filling, capping and sealing of 10ml (20ml) easy-open cap (aluminum-plastic cap) straight tube bottles.

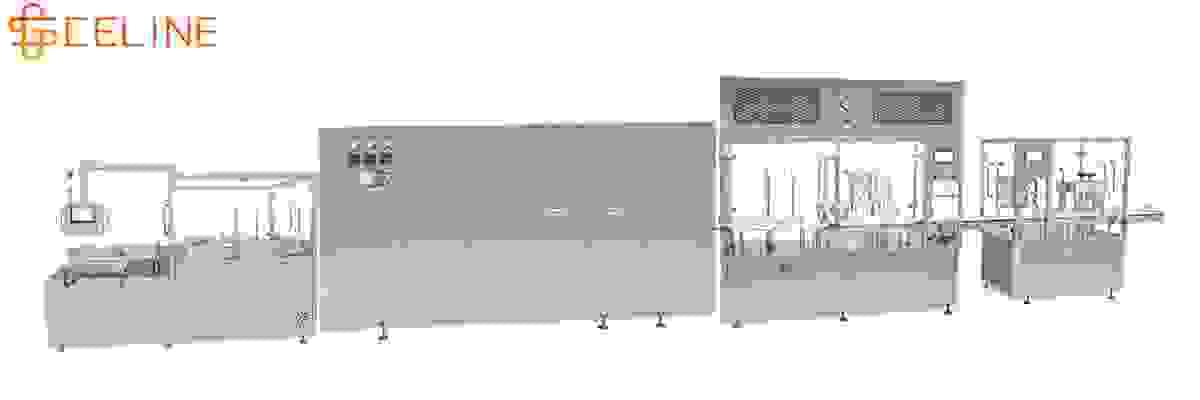

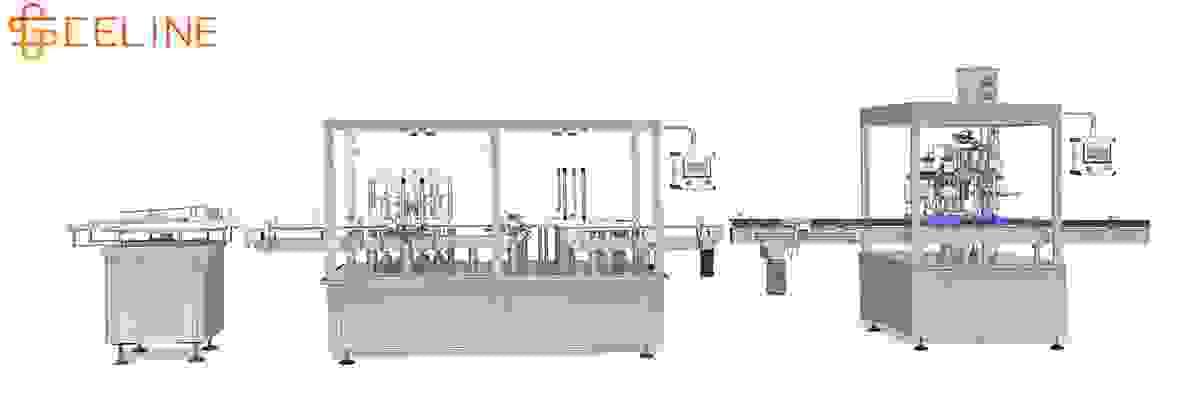

30-100ml Oral Liquid Bottle Filling Production Line

This liquid production line mainly used for 30-100ml molded bottles, from washing, drying, filling, capping and labeling.

Vial Bottle Integrated Production Line

The entire production line will be fully customized according to the product requirements, including production usage, filling contents, filling volume, filling speed, etc.

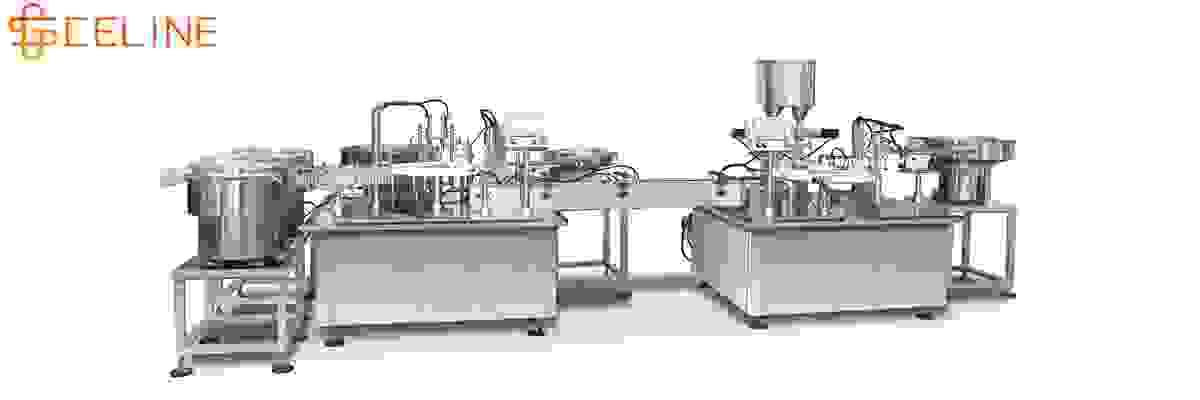

2-30ml Vial Liquid Filling Production Line

It is mainly used for cleaning, drying, filling, capping, and sealing 2-30ml easy-open cap silicone borosilicate tube bottles.

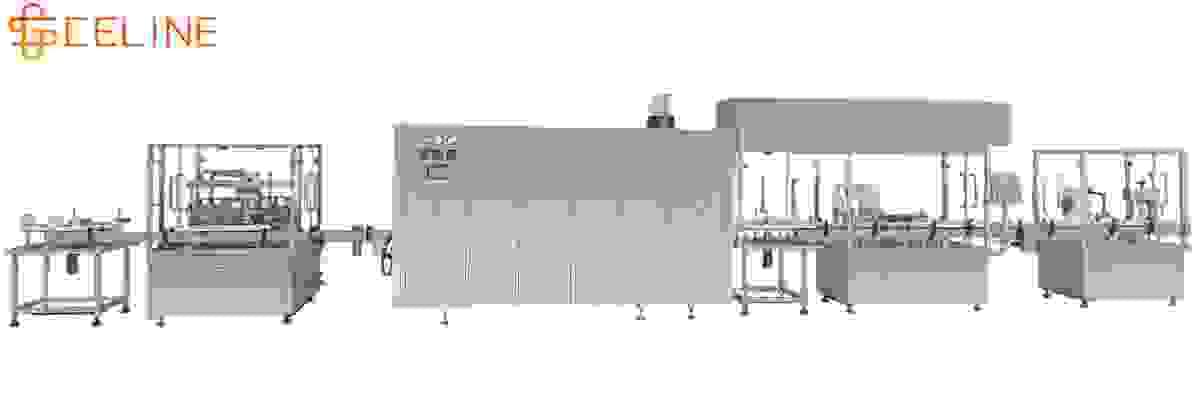

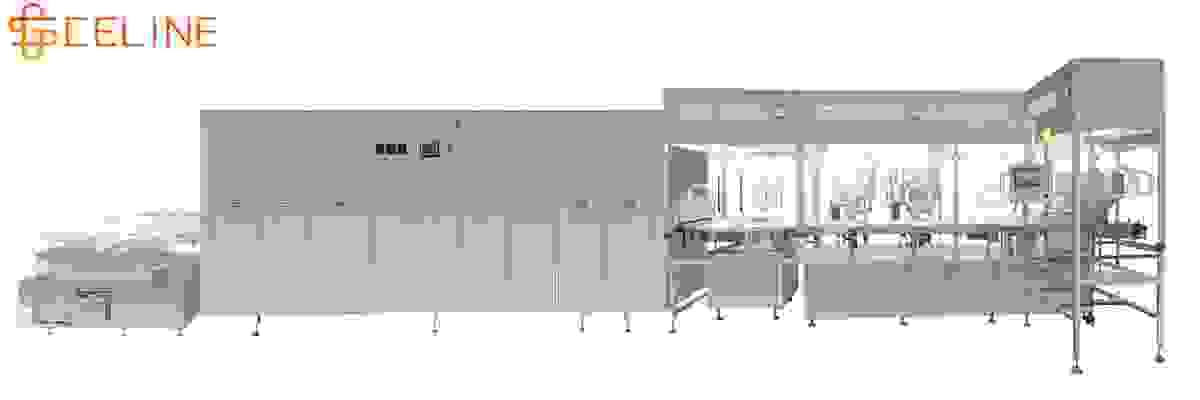

Large-volume Vial Infusion Bottle Integrated line

It is mainly used for cleaning, drying, filling, capping, and sealing of 30-500ml easy-open cap (aluminum-plastic cap) molded bottles.

Vial Powder Production Line

It is mainly used for cleaning, drying, screw dispensing, capping, and sealing of small vials such as 2-20ml vials.

Customized Integrated Production Line

External Gel Pusher Assembly Filling and Capping Production Line

This machine is suitable for filling and producing ointments, cosmetics, adhesives, latex, gels, and other products.

Aerosol Filling Capping Production Line for One Element / Two Element

This production line is equipped with the following products: rotary high-speed valve upper unit, centrifugal high-speed valve sorting machine, valve supply lifting machine, 6-station high-precision metering cylinder & single-unit booster pump, 6-head sealing & 6-head air filling integrated machine (positive pressure explosion-proof electrical box and explosion-proof human-machine interface).

Copyright © 2022 CELINE GROUP ALL RIGHTS RESERVED