In the pharmaceutical packaging field, blister packaging machines for vials play a crucial role, providing a solid guarantee for the development of the pharmaceutical industry.

The working principle of a blister packaging machine is ingenious and efficient. First, the vials to be packaged are placed orderly on a conveyor device, and the machine automatically transports them to the packaging station. Next, the heated and softened blister material, under the action of a mold, precisely covers the mouth of the vial, forming a tight seal. This process not only effectively prevents the drug from being contaminated by the external environment but also maintains the stability and efficacy of the drug. At the same time, the blister material has good transparency, facilitating the observation and identification of the drug.

In the pharmaceutical industry, blister packaging machines are widely used and indispensable. For injectable drugs, vials are one of the most common packaging containers. Blister packaging provides an extra protective barrier for drugs, preventing damage or leakage due to vibration, friction, and other factors during storage and transportation. For example, for some biological products and antibiotics, which have strict storage requirements, blister packaging in vials can ensure they maintain good quality within their expiration date. Furthermore, for medicines requiring light-proof storage, blister materials can be selected with light-blocking properties to further enhance protection.

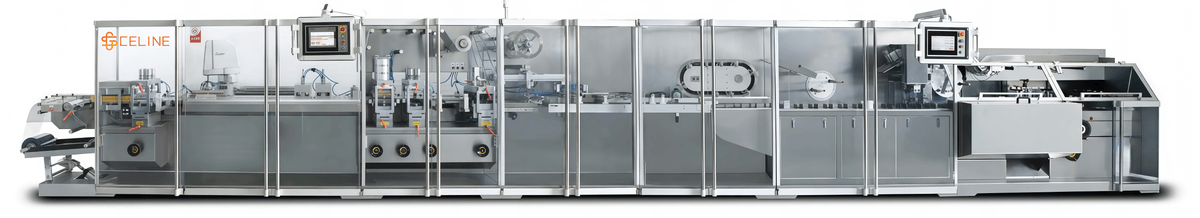

From a production efficiency perspective, blister packaging machines offer significant advantages. They automate the packaging process, greatly improving packaging speed and production efficiency. Compared to traditional manual packaging methods, they not only save substantial labor costs but also ensure consistent and standardized packaging. Moreover, modern blister packaging machines are typically equipped with advanced control systems that monitor various parameters during the packaging process in real time, such as temperature, pressure, and sealing effectiveness. If any abnormalities are detected, timely alarms and adjustments can be made to ensure stable and reliable packaging quality.

Beyond applications in the pharmaceutical industry, blister packaging machines also have potential for expansion in other fields. For example, in industries with high packaging requirements, such as cosmetics and health products, blister packaging in vials can also provide excellent protection and display effects, enhancing the added value of the products.

However, there are some issues to be aware of when using blister packaging machines. For example, regular maintenance is necessary to ensure the proper functioning of all components; at the same time, the quality of packaging materials must be strictly controlled to avoid affecting the packaging effect and drug quality due to material problems.

#BlisterPackingMachine #VialBottleBlister #VialBlisterMachine #BlisterMachine #BlisterProductionLine #CartoningMachine #AutomaticCartoningMachine #VialPackingLine