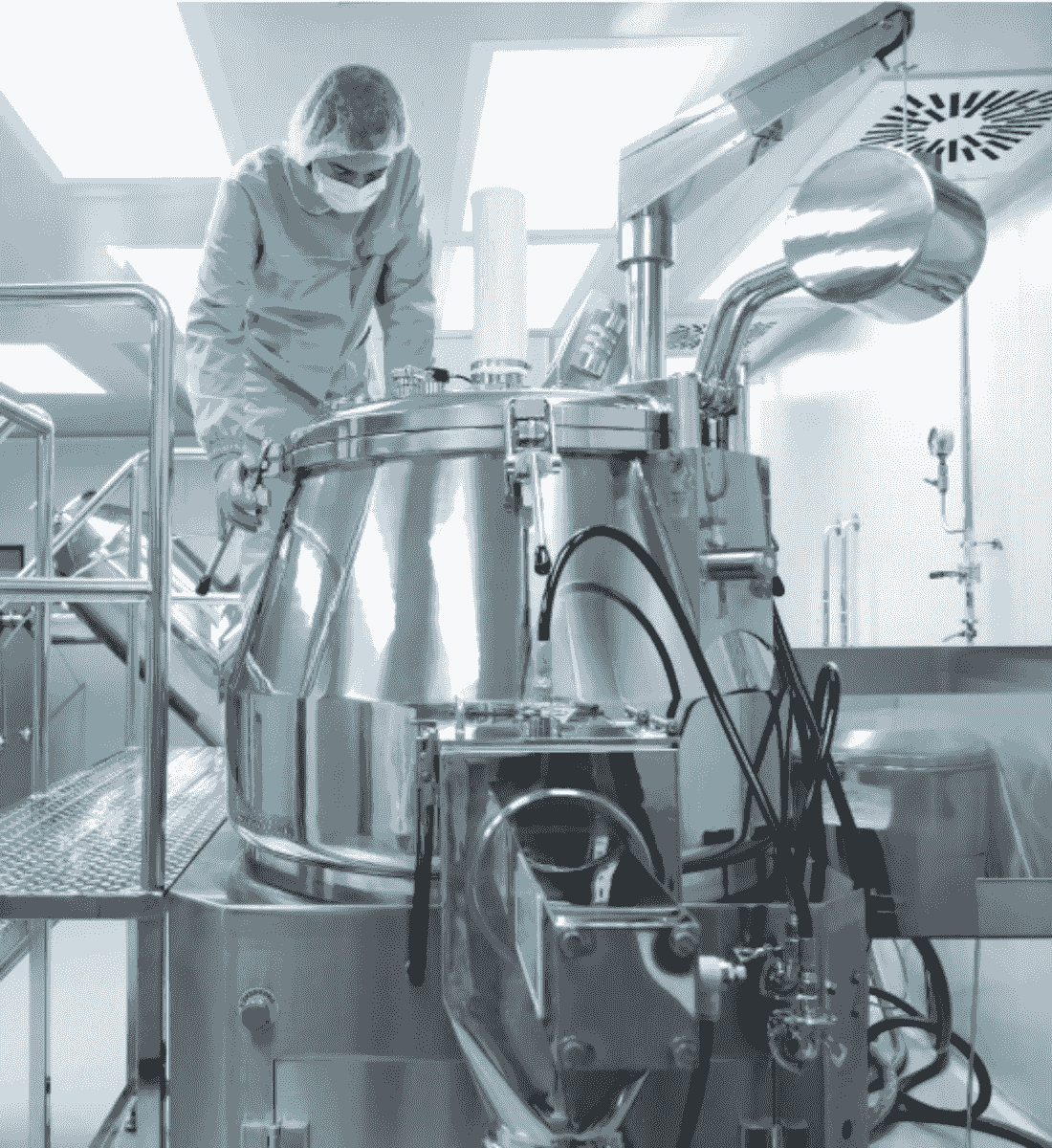

- Production Equipment

- Solid Material Preparation

- Solid Dosage Forms

- Liquid Dosage Forms

- Packing Machine

- …

- Production Equipment

- Solid Material Preparation

- Solid Dosage Forms

- Liquid Dosage Forms

- Packing Machine

- Production Equipment

- Solid Material Preparation

- Solid Dosage Forms

- Liquid Dosage Forms

- Packing Machine

- …

- Production Equipment

- Solid Material Preparation

- Solid Dosage Forms

- Liquid Dosage Forms

- Packing Machine

Extended Procurement & Integration Services

Beyond Single Equipment, Delivering Complete Solutions

As your trusted pharmaceutical equipment partner, we not only supply core machinery but also possess robust global supply chain integration capabilities. When your project involves special, non-standard, or cross-category equipment, our One-Stop Integrated Procurement Service can resolve complex supply chain challenges, ensuring seamless compatibility of all components and accelerating project commissioning.

Featured Integrated Procurement Cases

Case 01: Facilitating a "Turn-Key" Equipment Package for a New Pharmaceutical Plant in Africa

Client Challenge:

- A client building a new plant in Africa required a complete Oral Solid Dosage (OSD) production line (from granulation to packaging) but lacked international procurement experience and expertise.

- The client sought a reliable partner capable of supplying all equipment and managing all cross-border complexities.

Our Integrated Solution:

- Holistic Layout Design: Based on their capacity and formulation needs, we proposed a complete equipment list and layout covering mixing, granulation, drying, tableting, coating, blister packing, and cartoning.

- “Turn-Key” Procurement: We acted as the purchasing agent for different equipment base on user requirement sheet.

- End-to-End Management: Provided full-process management encompassing factory audits, contract negotiation, joint FAT, international shipping, customs clearance, and on-site installation guidance.

- Unified Training: Coordinated unified English-language remote training sessions from all equipment suppliers.

Project Outcome:

- Hassle-Free Experience: The client completed the entire complex equipment procurement through a single point of contact (us).

- Quality Assured: All equipment met cGMP and international standards, passing our stringent pre-shipment inspections.

- Successful Commissioning: The project was delivered on schedule, and the plant is now successfully operational.

Case 01 Video

Automatic Blister & Cartoning Machine

Advantages:

- End-to-end automation

- Cusomizable configuration, include blister size and shape, carton box size, working speed, match working space request, etc.

- High speed performance, more efficiency

- GMP & FDA compliance

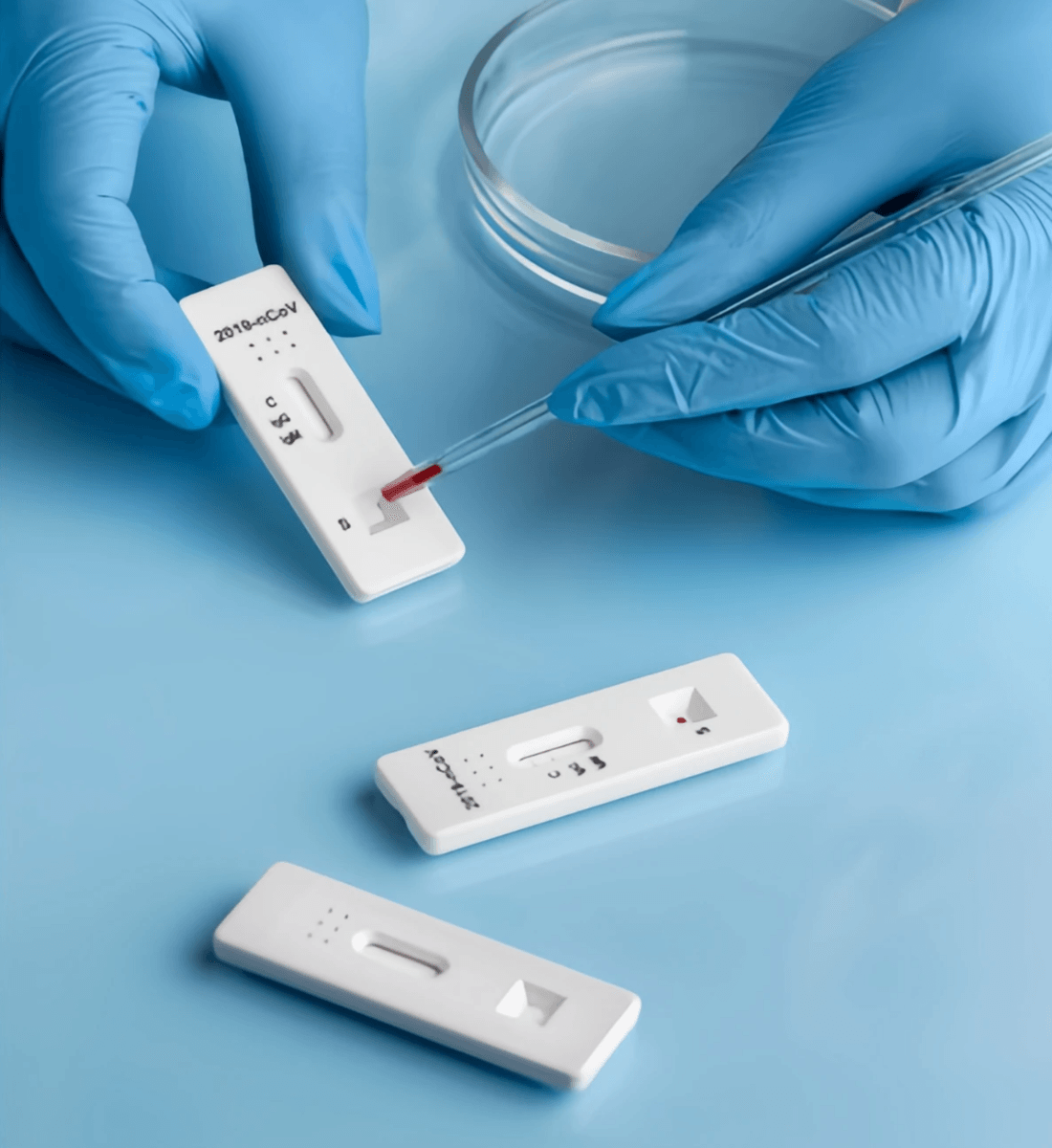

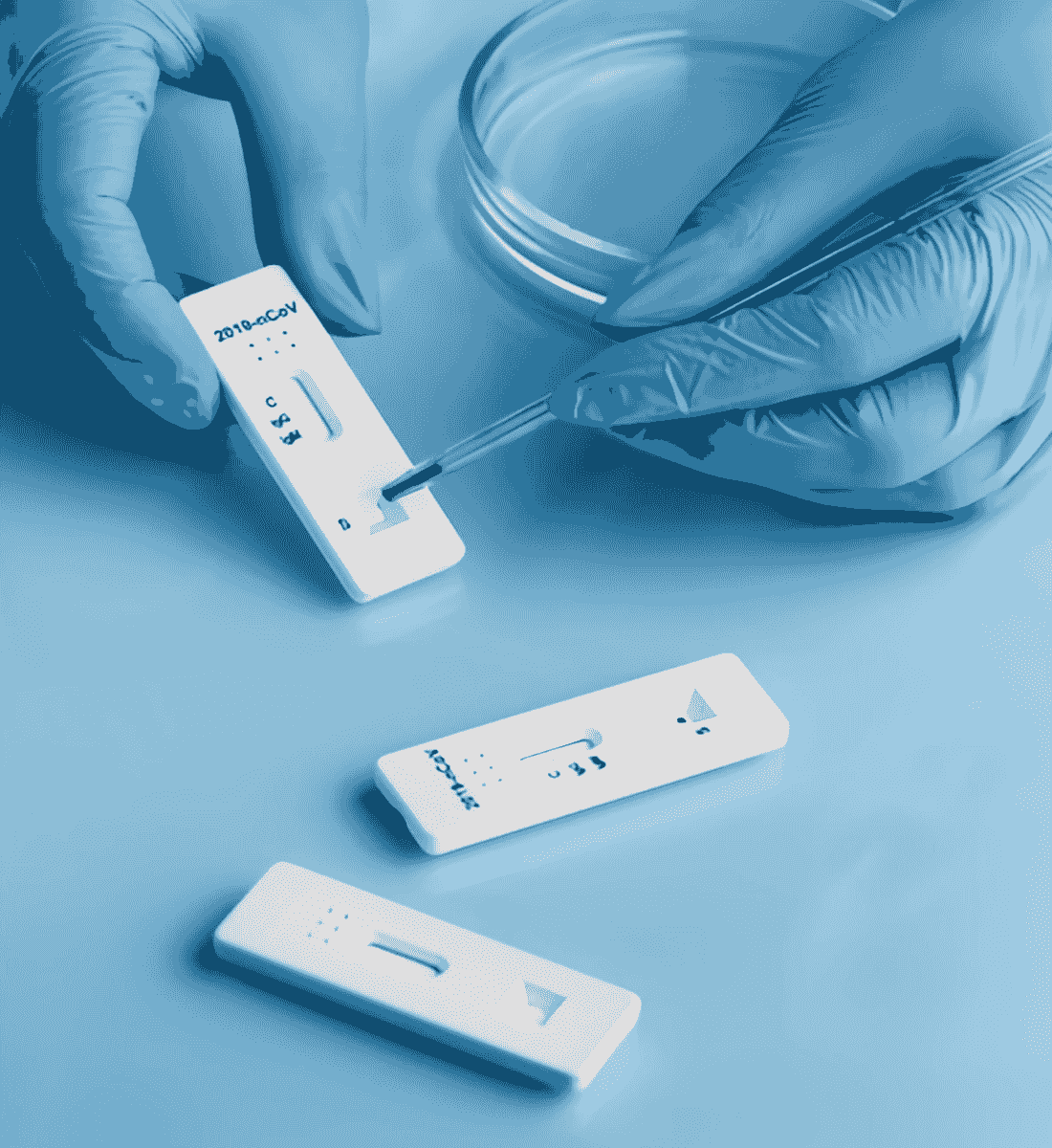

Case 02: Building a Complete Automatic Testing Cassette Production Line for a New Pharma Factory in Middle East

Client Challenge:

- The client is a new factory, and we provided design, material supply, and local installation services for their cleanroom and laboratory. The client faced risks such as multiple suppliers, mismatched technical interfaces, and lengthy cross-border coordination cycles.

Our Integrated Solution:

- Comprehensive Procurement: As the main coordinator, we undertook the entire procurement task for all diagnostic test kit-related products, including fully automated assembly equipment, large test plates for HCG and infectious disease testing, droppers, desiccants, blank test card holders, etc.

- Technical Integration: Our engineers liaised with various suppliers to ensure 100% compatibility of all materials (test plates, droppers, desiccants, and test cards).

- Product Sourcing: For each product, we contacted at least three suppliers, compared samples, prices, and delivery times, and selected the best supplier.

- Unified Delivery: After sampling and inspection of all products from various suppliers, we consolidated the shipments and provided single-point responsibility after-sales support.

Project Outcome:

- Time Savings: We shortened the client's procurement and coordination time by nearly four months.

- Cost Optimization: Through centralized negotiation and optimized logistics, the overall cost was 15% lower than the client's budget.

- Risk Elimination: All technical interface issues were resolved before shipment, and on-site installation and commissioning were successful on the first attempt.

Case 02 Video

Automatic Testing Cassette Assembling Packaging Machine

Working Process Include:

- Testing Sheet cutting into strip

- Cassette assemble with strip, front and back part cassette

- Put assembled cassette, drops, desiccant into aluminum foil bag and sealing.

Does Your Project Face Similar Challenges?

- Need to procure supporting systems beyond core equipment?

- Struggling with coordinating and managing multiple international suppliers?

- Want a trusted partner to take full responsibility for the entire procurement process?

Contact us today for your tailored Integrated Procerement Solution!

Copyright © 2022 CELINE GROUP ALL RIGHTS RESERVED