A blister packaging machine is an automated packaging equipment widely used in the pharmaceutical, food, electronics, and medical device industries. It protects, displays, and facilitates the use of products by sealing them in cavities formed by plastic sheets (blisters) and aluminum foil (or composite film). The following is a detailed description of its functions and uses:

I. Core Functions

1. Automatic Forming

By heating plastic sheets (such as PVC, PET, PP, etc.), the machine uses molds to stamp or thermoform the plastic into blister cavities that match the shape of the product.

2. Precise Filling

Products such as tablets, capsules, food, and small parts can be manually, semi-automatically, or fully automatically placed into the blister cavities with high precision, reducing waste.

3. Efficient Sealing

Aluminum foil or composite film is placed over the blister, and heat and pressure are applied to tightly seal it to the plastic sheet, creating a sealed barrier.

4. Punching and Cutting

The continuously arranged blisters are separated into individual sections (such as pharmaceutical blister packs), or cut into the desired shape according to the set dimensions.

5. Detection and Rejection

Integrated vision inspection, metal detection, or missing-part detection systems automatically identify and reject products that are missing, damaged, or have defective seals.

6.. Coding and Labeling

Production date, batch number, expiration date, and other information can be printed on the aluminum foil or plastic sheet to meet industry traceability requirements.

II. Main Uses

Pharmaceutical Industry

- Drug Packaging: Sealed packaging of tablets, capsules, oral liquid bottles, etc., providing moisture protection, light protection, and extended shelf life.

- Dosage Control: Each blister is individually packaged, making it convenient for patients to take the correct dosage and preventing contamination.

- Compliance: Complies with GMP (Good Manufacturing Practice) requirements and supports child-resistant packaging designs.

Food Industry

- Snack Foods: Single-serving packaging of chocolates, candies, jellies, etc., maintaining freshness.

- Convenience: Easy to carry and distribute, suitable for travel packs or promotional packaging.

Electronics and Daily Chemicals

- Small Parts Packaging: Button batteries, electronic components, screws, etc., providing anti-static and anti-oxidation protection.

- Cosmetics: Face masks, lipsticks, perfume samples, etc., ensuring hygiene and aesthetic appeal.

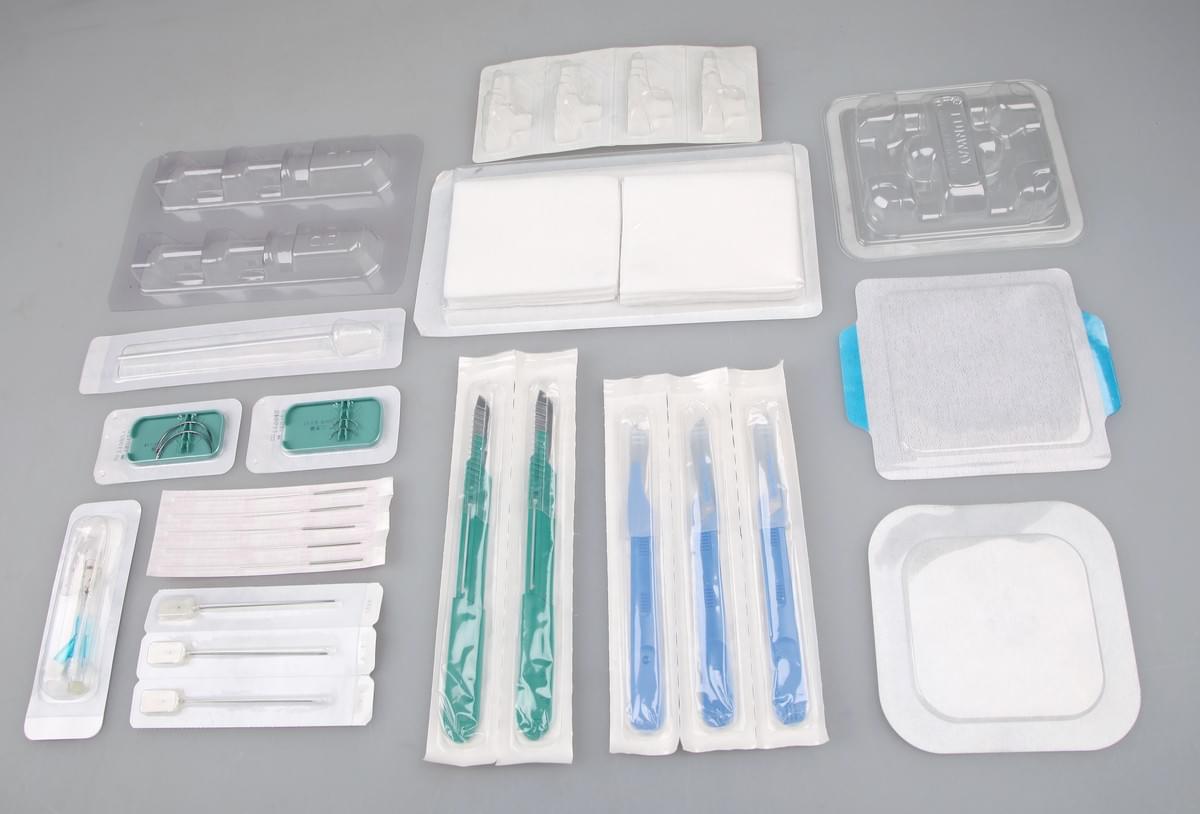

Medical Devices

- Sterile Instruments: Surgical blades, syringes, catheters, etc., ensuring sterility until use. Industrial Applications

- Tool Packaging: Small tools and accessories, facilitating inventory management and retail display.

III. Technical Advantages

- High-Efficiency Production: Speeds of up to several hundred blisters per minute, suitable for large-scale assembly line production.

- Strong Protection: Sealed design protects against moisture, dust, and oxidation, extending product life.

- Transparent Display: Transparent plastic sheets provide a clear and intuitive view of the product.

- Flexible Design: Blister shapes and sizes are customizable to meet different product needs.

- Environmentally Friendly Options: Supports the use of biodegradable materials (such as PLA), aligning with sustainable development trends.

IV. Equipment Types

- Semi-automatic type: Manual product filling, suitable for small-batch production.

- Fully automatic type: Integrates forming, filling, sealing, and inspection, suitable for large production lines.

- Rotary type: High-speed continuous production with extremely high efficiency.

- Flatbed type: Suitable for thick sheets or deep-drawn products.

V. Development Trends

- Intelligentization: Integration of Internet of Things (IoT) technology for real-time monitoring of production data and predictive maintenance.

- Modular design: Quick mold changeover to adapt to multi-variety, small-batch flexible production.

- Green packaging: Promoting the use of environmentally friendly materials to reduce carbon emissions.

VI. Precautions

- Material Selection: Compatible plastics and sealing materials must be selected based on product characteristics.

- Maintenance Requirements: Regular cleaning of molds and heating systems is necessary to ensure sealing quality.

- Regulatory Compliance: Pharmaceutical and food industries must comply with regulations from regions such as the FDA and EU.

Blister packaging machines, through high automation and precise control, not only improve packaging efficiency and product safety but also enhance the consumer experience, making them an indispensable key equipment in modern industry.