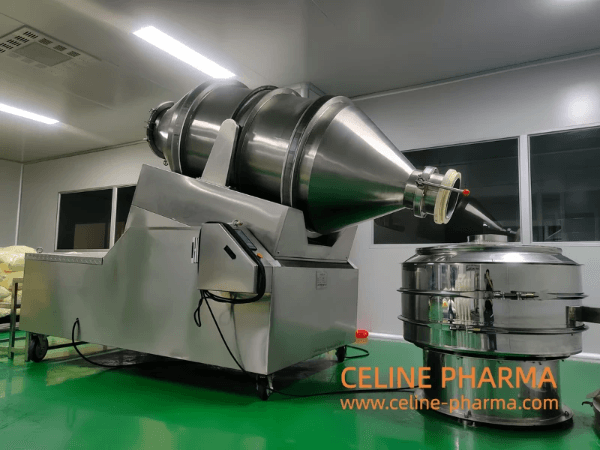

Two-dimensional motion mixers, as highly efficient material mixing equipment, are widely used in the pharmaceutical, chemical, and food industries. Their workflow, relying on the equipment's structural design and motion patterns, achieves rapid and uniform mixing of materials. The following will analyze the workflow of a two-dimensional motion mixer in detail from three stages: feeding, mixing, and discharging.

I. Feeding Stage: Orderly Filling, Laying the Foundation for Mixing

Before starting the mixing operation, the feed inlet of the two-dimensional motion mixer's mixing drum must be opened. The feeding method can be manual or automatic feeding using conveyor equipment, depending on actual production needs. When feeding manually, the operator must carefully pour the material into the feed inlet to avoid spillage, waste, and contamination. Automatic feeding typically uses equipment such as screw conveyors or vacuum feeders to accurately transport the material into the mixing drum. To ensure mixing effectiveness, the material loading amount must be controlled within a reasonable range, generally not exceeding 70% of the mixing drum's volume. This ensures sufficient space for material movement within the drum while improving mixing efficiency.

After feeding is complete, close the feed inlet and ensure a good seal to prevent material leakage or the entry of external impurities during mixing, which could affect the mixing quality. Simultaneously, check that the equipment's transmission and control systems are in normal working order to prepare for the mixing process.

II. Mixing Stage: Compound Motion for Uniform Mixing

Start the two-dimensional motion mixer, and the equipment's transmission system begins operation. The motor outputs power, which is reduced in speed and increased in torque by a reducer, and then transmitted to the rotating shaft of the mixing drum via a coupling and drive chain. At this time, the mixing drum begins a compound motion of revolution and rotation.

During revolution, the mixing drum revolves around a central axis, causing the material inside the drum to move as a whole, creating a large-scale convection within the drum. Rotation, on the other hand, is the mixing drum's own rotation, which causes the material to tumble and shear within the drum. The superposition of these two motions causes the material to be continuously thrown up, fallen, tumbled, and interwoven within the mixing drum. For example, in the pharmaceutical industry, when mixing multiple drug powders, this compound motion allows powders of different particle sizes and densities to come into full contact, achieving a uniform mixing effect in a short time.

During the mixing process, operators can set the mixing time and speed through the control system according to the material characteristics and mixing requirements. For materials with good flowability and easy mixing, the speed can be appropriately reduced and the mixing time shortened; while for materials with high viscosity and difficult mixing, the speed needs to be increased and the mixing time extended to ensure that the mixing uniformity meets production standards. Simultaneously, the control system monitors the equipment's operating status in real time. If any abnormality is detected, an alarm will be issued promptly and the equipment will be stopped to ensure the safety of equipment and personnel.

III. Discharge Stage: Precise Control, Completing the Mixing Operation

When the mixing time reaches the set value, the mixer stops operating. At this time, the discharge port of the mixing drum is opened, and the material is discharged from the discharge port under its own gravity. For materials with good flowability, unloading can be completed directly by gravity; if the material is highly viscous or has poor flowability, the mixing drum can be gently shaken or compressed air can be used to facilitate smooth discharge.

After discharge, the mixing drum needs to be cleaned to prevent residual material from affecting the quality of the next mixing operation. During cleaning, a soft brush and detergent can be used to scrub the inner wall of the mixing drum. For stubborn stains, high-pressure water rinsing can be used (the pressure must be controlled within an appropriate range to avoid damaging the equipment). After cleaning, check whether the mixing drum, sealing device, and other components are intact to prepare for the next use.